Composite bicycle front fork

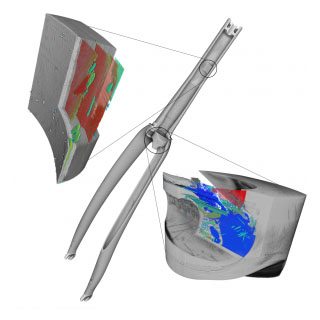

In this use case a carbon fibre front fork of a bicycle was analyzed using X-ray micro CT imaging using the XRE CoreTOM. The entire front fork was scanned in 30 minutes at a resolution of 160 µm. This overview scan provides a 3D image of the internal structure of the composite in a non-destructive manner. From the overview scan it was clear that numerous defects were present in the front fork, while the object appeared perfectly intact based on visual inspection.

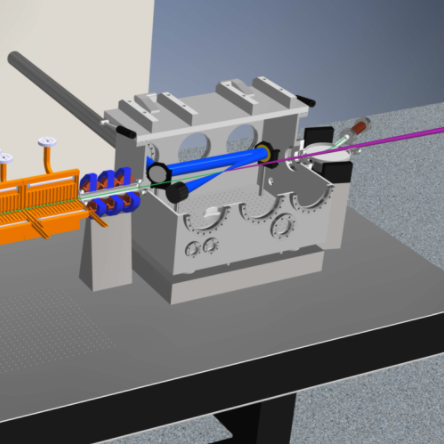

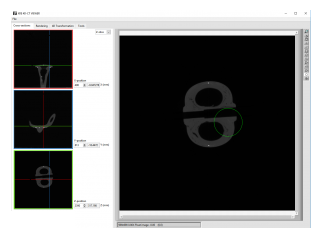

Using the Volume of interest selection (VOIS) tool of the CoreTOM system, interesting regions could be selected on the overview CT image and the system would automatically zoom into the selected region for high resolution detailed scans.

Two detailed scans were performed on the complete front fork sample using the XRE VOIS feature. One detail scan of the central part of the object at a resolution of 15 µm and one detail scan of 5 µm resolution, or a 32x magnification, on the upper part of the front fork. In the upper part, fractures parallel to the layered carbon fibre structure could be visualized and these were most likely formed during extreme (mis)use of the bicycle fork. In the detailed scan of the central part of the object, both fractures and air bubbles inside the composite could be visualised. The concentration of numerous air bubbles in some layers of the composite could indicate problems during the production process of the composite part.