Bread, not sliced, but 3D analysed

Zeelandia, one of the leading enterprises in the bread and bakery sector, joined forces to gain insights into the 3D structure of bread.

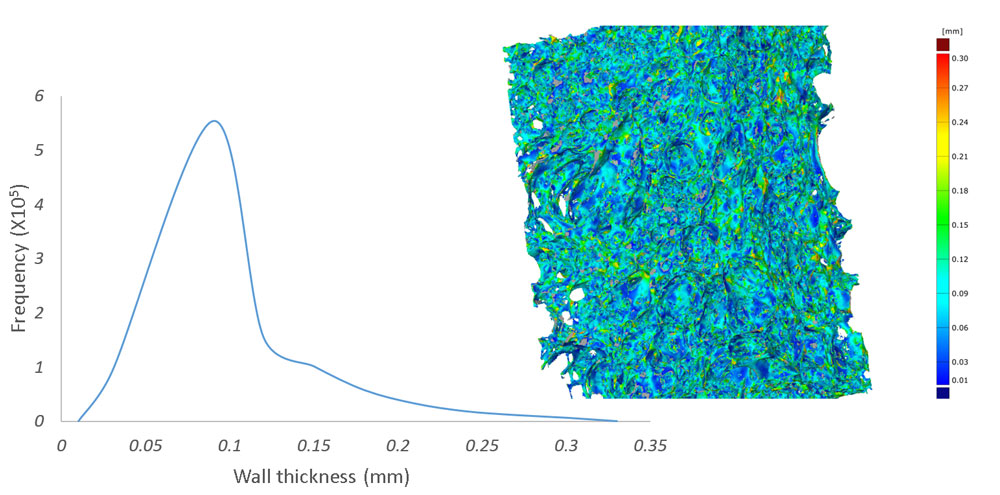

It is obvious that when trying to improve processes, a fundamental knowledge of your product is necessary. In case of bread, many structural and chemical parameters are involved: chemical composition, volume percentage of voids, wall thickness of individual pore systems, distribution of ingredients, density variations, void connectivity, etc. All those fundamental parameters greatly contribute to the structure, mechanical properties and taste of the bread itself. Of course, a thorough understanding of the properties of the bread is essential for both a healthy society and a pleasant food experience for the end user.

But how do you quantify those structural parameters without slicing your bread? Not only you might influence the structure of the bread by slicing, but moreover, in the end you want to track all the structural parameters in function of the preparation/baking process. Because, during the complex process of bread making all the fundamental parameters can change and thus influence the formation of the end product. Thus, In order to truly understand and optimize your product, non-destructive analysis tools are mandatory to follow the same sample over time during different processing steps.

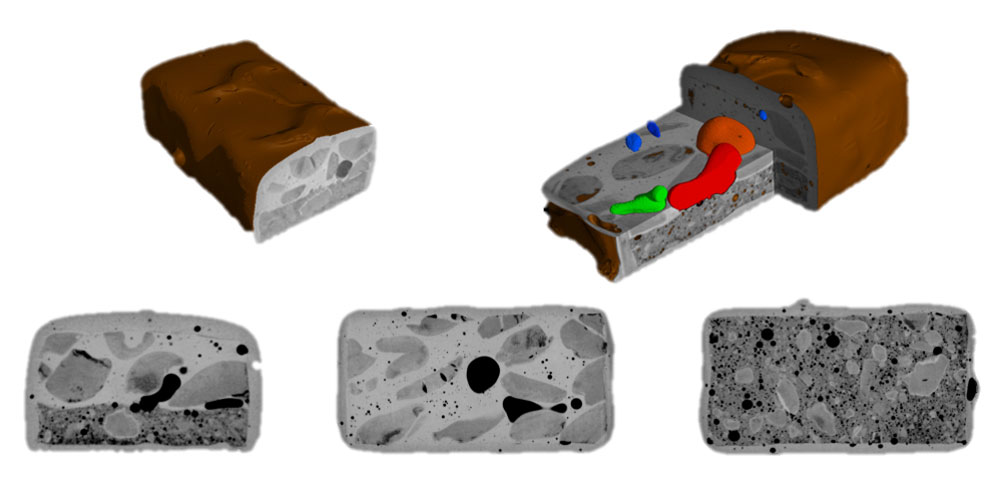

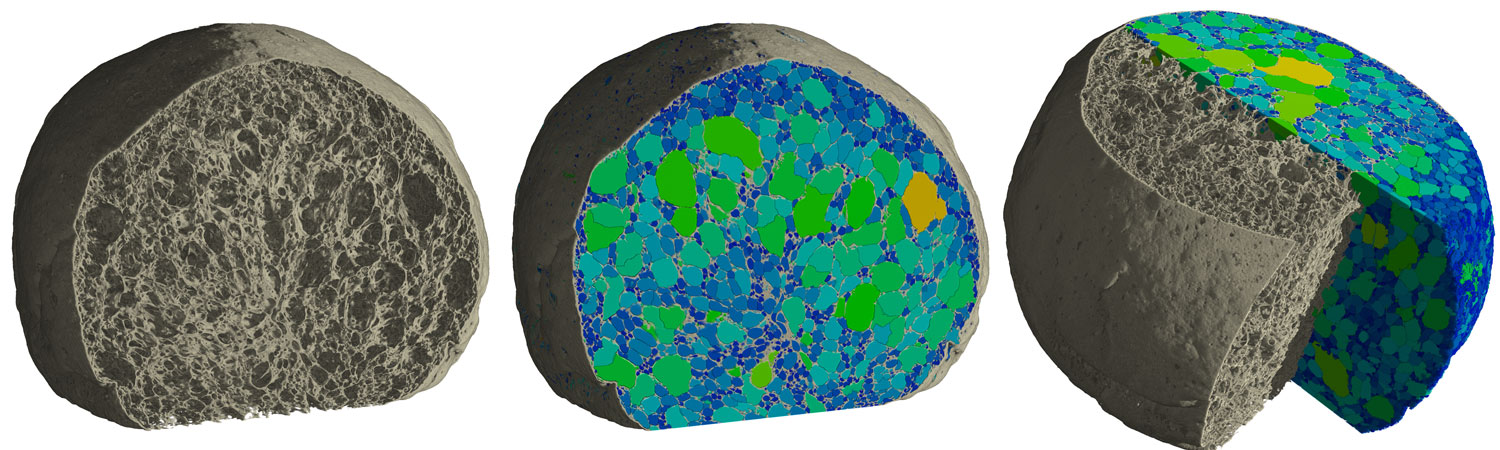

The bread was scanned with high resolution X-ray computed tomography to reveal the inside. We were not only able to visualize the internal structure, but also quantify the most important structural parameters. By doing so, a better understanding of the internal properties was obtained. Some rendered segmentation views of the pore structure inside are shown below. The colour code corresponds with the size of the pore.

A smaller piece inside the bread was digitally extracted and a wall thickness measurement was applied. Blue is a small wall thickness, red is a big wall thickness.

The X-ray inspection services of XRE are not only limited to bread but extent to all food and agrifood products such as seeds, candy bars, fruits, nuts, plants … Also packaging, contamination, food transformation and different contact zones between materials can be investigated with the help of our experts.

An example below demonstrates a scanned and segmented candybar. Not only volume% of chocolate, nuts, sugar and voids can be extracted but also shape parameters, orientation and connectivity.